Grand battement jeté and pirouettes in manufacturing

This year, manufacturing has been performing grand battement jeté or throwing up a straight working leg, to put it in ballet terms; and with each quarter the leg moved higher and higher, albeit slower in the third quarter than before. In this case, the idea is mostly about the rapid turnover growth in manufacturing, pushed up by a temporary help, i.e. prices, rather than through developing metaphoric muscle power (e.g. productivity) in regular training sessions.

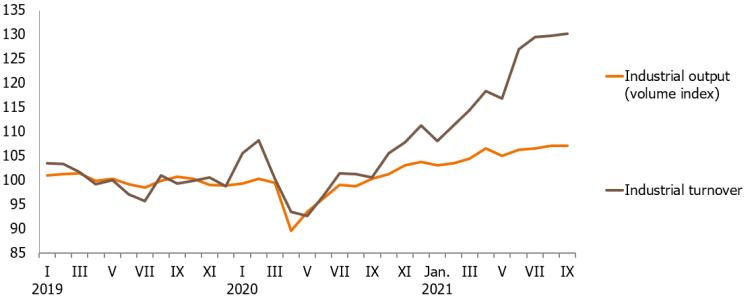

Nevertheless, it should be noted that the output volume index, which is really the true reflection of the "physical condition" of manufacturing, also shows respectable growth exceeding the pre-pandemic level by 8%. And the growth could have been even higher, but for different issues with shortages of materials and components, logistics and delivery delays.

Chart 1. Manufacturing output (volume index) and turnover (2019=100%)

This year, the story of global manufacturing highlights two worrying plot lines: prices/costs and deficit of various components/raw materials.

1) It may seem unbelievable, but the story of rising prices is partly good news: export prices move up faster than that those of imports and, given the composition of Latvian economy, it is able to earn more profit during this period. This year the increase in prices has mostly been driven by factors beyond our control – the rise in oil prices and the extensive government support programmes during the pandemic, and the surge in these costs can be felt globally.

2) The deficit of various materials and components is also an issue encountered worldwide, caused by various factors: an increasing demand for specific goods during the pandemic, lower output caused by downtime in different plants, etc. Production of goods suffers from shortage of semiconductors, several metals, wood chips, pigments of various colours for producing paints and plaster, etc.

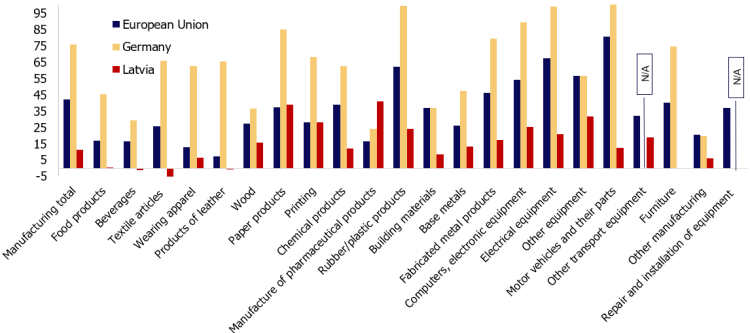

Companies in Latvia are smaller on average. Although they are characterised by lower productivity and innovation capacity, in the current situation they have demonstrated better flexibility in addressing challenges than on average in the European Union, particularly in Germany, the stronghold of industrialisation. It is in Germany that the role of materials and equipment as a limiting factor has currently increased considerably in the business surveys in comparison with the pre-pandemic (Chart 2).

In Latvia, shortages of raw materials are mostly observed in the manufacture of pharmaceutical products and paper products. Meanwhile, in mechanical engineering, manufacture of electrical and electronic equipment, fabricated metal products, and rubber and plastic products, i.e. sectors facing acute problems with raw materials in other European countries, the situation in Latvia is relatively less dramatic: the issue of materials and components has aggravated, albeit more moderately than in other countries. A major reason in this case is better adaptation skills.

Chart 2. Shortage of materials/equipment as a factor limiting production, changes in Q IV 2021 vis-à-vis Q IV 2019 (percentage points)

How do businesses adapt in Latvia? To the extent possible, businesses develop "recipes" for their products using the components available in warehouses, use unconventional supply chains, e.g. brokers, enter into bigger component supply contracts thus stocking up on supplies, scrupulously planning and diversifying suppliers and materials etc. For example, this article in Delfi tells us about adaptation to semi-conductor shortage circumstances.

One can only admire the pirouettes demonstrated by Latvian businesses who have seen so many challenges and changing rules of the game. Any top-level ballet dancer could envy the perfect demonstration of their nimble movements. Although manufacturing growth slowed down in the last quarter, it still persistently continues to develop.

As a fan of ballet and manufacturing, I would like to wish businesses endurance in these still challenging circumstances. Unfortunately, analysts do not promise fast improvement in the situation globally; their forecasts mostly project supply chain disruptions up to late spring next year. This also holds true about price hikes that could moderate only next year.

Textual error

«… …»